Vibration Monitoring Of The Screens

Vibration Monitoring Of The Screens. The echo wireless vibration monitoring system can safely "look" at the machines health several times per day and provide data to your existing vibration monitoring systemhe system allows the reliability-centered maintenance team to monitor more channels with fewer resources by eliminating the collection of vibration data on …

vibration monitoring of the screens

Bently Nevada 3500 Vibration Monitoring System vibration monitoring suitable for machinery protection applications. - Assembly consists of the full-size 3500 Rack available in 19” EIA rail-mount, panel-cutout-mount, and bulkhead–mount versions.

vibration monitoring of the screens - chanelcar.fr

Vibration Monitoring On Vibrating Screens Sensors to monitor vibration in Vibrating Screens Vibration Vibration monitoring for the Coal. Remote Vibration Monitoring System (RVMS) vibration monitoring is the key to reduce the , taking screen shots and even all the data of trend and waveform , Remote Vibration Monitoring System RVMS_Doc#CIG .

vibrating screen condition monitoring - BINQ …

Reliable Detection of Damage on Vibrating Screens. rating conveyors, vibrating screens and customer-specific solutions. Spaleck is … mers plants – Spaleck was looking for a reliable monitoring solution. The aim … analyses the overall vibration condition in accordance with DIN ISO. 10816 as … »More detailed

Vibrating Screen Exciter Gearbox - Bearing defects …

Hi all, How do you monitor vibrating screen exciter gearboxes for deterioration and reliability risks? Do any of you monitor vibrating screens exciters for bearing defects using routine vibration analysis, how do you cope with the harsh environment?

Assessing vibration: a technical guideline

Assessing vibration: a technical guideline 1 1.1 Overview Where occupants can detect vibration in buildings, this may potentially impact on their quality of life or working efficiency. In contrast, people tolerate much higher vibration values in vehicles than in buildings.

Condition-Based Monitoring: Vibration Recorders …

Real Time Vibration Monitoring Systems and Recorders. A broken piece of equipment can translate to thousands of dollars in associated costs. Real-time vibration monitoring of critical equipment in your operation is the best way to prevent downtime, and a data logger which records vibration levels will help prevent equipment damage while it’s in transit.

Vibration Monitoring | Fluke

Vibration monitoring devices use accelerometers to measure changes in amplitude, frequency, and intensity of forces that damage rotating equipment. Studying vibration measurements allows teams to discover imbalance, looseness, misalignment, or bearing wear in …

A Brief Tutorial on Machine Vibration

A Brief Tutorial on Machine Vibration by Victor Wowk, P.E. Machine Dynamics, Inc. The purpose of this tutorial is to provide sufficient knowledge to understand machine vibration diagnosis. You may be tasked with solving a vibration problem, or you may be overseeing someone else and you need to understand the process.

The Role of Vibration Monitoring in Predictive Maintenance

The Role of Vibration Monitoring in Predictive Maintenance Dr. S. J. Lacey, Engineering Manager Schaeffler (UK) Limited 1. Introduction As greater demands are placed on existing assets in terms of

Sensors for Monitoring Vibratory Screens and …

Vibration monitoring of vibrating screens and feeders is critical to determining machinery health and preventing overloading or catastrophic damage to equipment. Because this type of equipment is intended to operate with high levels of vibration, low sensitivity high range sensors are optimal.

Accelerometers Review and Application | …

Accelerometers Review and Application. ... Vibration monitoring programs are utilized in industries such as automotive manufacturing, ... often the accelerometer is used to present landscape or portrait views of the devices screen, based on the way the device is being held.

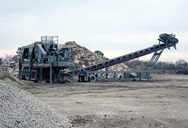

Mining and Quarrying Industry - Hansford Sensors

Vibration sensors for mining & quarrying for use in pumps, fans, gearboxes and motors in mining, ... Vibration monitoring is key to the success of a preventative maintenance programme. ... of monitoring and maintaining a wide range of machines used in quarrying and mining, including motors, gearboxes, pump, screens, crushers and conveyors.

Anomaly Detection using Vibration Analysis with Machine ...

vibration data of the equipment in normal condition as a reference and then displays the degree of deviation from the reference as a score on the screen in real-time. The evaluation kit is designed to enable applicability verification of OKI’s vibration analysis algorithm according to the following steps timed with the customers periodic

Condition monitoring - Wikipedia

Condition monitoring (or, colloquially, CM) is the process of monitoring a parameter of condition in machinery (vibration, temperature etc.), in order to identify a significant change which is indicative of a developing fault.It is a major component of predictive maintenance.The use of condition monitoring allows maintenance to be scheduled, or other actions to be taken to …

mining gold mill condition monitoring vibration

mining gold mill condition monitoring vibration. The mining industry is a heavy industry where condition monitoring equipment must survive mechanical and environmental forces The SPM product range includes portable instruments online systems and accessories specifically suited for shock pulse monitoring of rotating machinery and vibration monitoring equipment for …

Vibration Measurement for Rotatory Machines

Vibration Measurement For Rotatory Machines 1 1 INTRODUCTION In summer of 2011 I started to work for Hi-Teckno Engineering and a consulting office. During that time my task was to do maintenance work for centrifugal fans at energy plants and stone mills all around Finland. Because the core business of the company was vibration measurements, I

Vibration Monitoring - Vibrationdamage.com

Vibration monitoring done on behalf of contractors can be so variable, in execution (note "professional" installation at left for a good example of how not to install a blasting seismograph), interpretation, and reporting, that it might be highly advisable to do your own vibration monitoring, as a check on the contractor monitoring.