Milling and processing - IRRI Rice Knowledge Bank

In an ideal milling process this will result in the following fractions: 20% husk, 8−12% bran depending on the milling degree and 68−72% milled rice or white rice depending on the variety. Total milled rice contains whole grains or head rice, and brokens. The by-products in rice milling are rice hull, rice germ and bran layers, and fine brokens.

Milling by-products - IRRI Rice Knowledge Bank

The rice husk, also called rice hull, is the coating on a seed or stone of rice. It is formed from hard materials, including silica and lignin, to protect the seed during the growing season. Each kg of milled white rice results in roughly 0.28 kg of rice husk as a by-product of rice production during milling.

Rice Milling — Vikaspedia

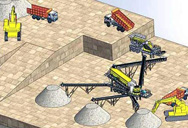

Rice milling : process description. Paddy Cleaning - Essential for removal of undesired foreign matter, paddy cleaning is given utmost importance to ensure proper functioning of the Rice Milling machinery.Rough rice is passed through a series of sieves and closed circuit aspiration system is provided to remove dust and light impurities through positive air suction.

Modern Rice Milling Process : Steps & FlowChart ...

Paddy Rice cleaning process also called rice paddy cleaning process. It is first step in rice milling systems after rice paddy comes for milling process in rice mill from Rice farms. Paddy always comes up having a lot of external material including weed, soil, seeds, etc.

Rice Milling Manual - IRRI Rice Knowledge Bank

Rice Milling 1 Introduction The objective of a rice milling system is to remove the husk and the bran layers from paddy rice to produce whole white rice kernels that are sufficiently milled, free of impurities and contain a minimum number of broken kernels. The milling yield and quality of rice is

Rice Milling Technology

Rice milling is the process of removing the husk and bran layer to produce white rice. Rice milling can be undertaken as: Rice milling can be undertaken as: • A one step milling process where the husk and the bran are removed in one pass and white rice is produced directly from the paddy.

What is Rice Milling Process?

The modern rice milling process 1. Pre-cleaning:Paddy cleaner is the most essential equipment in a rice mill, as it separates all the impurities like dust, straw, sand, clay and heavy particles of even an uneven sizes from paddy.The advantages with the paddy cleaner are that increases the life of stone rollers and the percentage of oil in bran.

By-products - IRRI Rice Knowledge Bank

The rice husk, also called rice hull, is the coating on a seed or stone of rice. It is formed from hard materials, including silica and lignin, to protect the seed during the growing season. Each kg of milled white rice results in roughly 0.28 kg of rice husk as a by-product of rice production during milling.

Rice Milling | SAIIA

Background Rice Milling Company (Pvt.) Limited (RMC) mills, processes and packs local varieties of rice both for the local market in Malawi and for export, mainly within the Sub-Saharan African region. RMC also trades in different types of rice which it imports for distribution and sale throughout Southern Africa. 50% of RMC is owned by … Rice Milling Read More »

Design and Development of Rice Milling and Grinding Machine

This results in many broken kernels, a low white rice recovery of 50-55% and head rice yields of less than 30% of the total milled rice (IRRI, 2014). The steel husker is in fact more than a …

RICE INSPECTION HANDBOOK

computing the number of filled rice containers loaded aboard the carrier, observing the condition of the rice containers loaded aboard the carrier, sealing the carrier, if practicable, and certifying the results. Checkweighing. The process of weighing a selected number of containers from a rice

Rice Milling Systems (English) - YouTube

29.01.2013 · Paddy and rice processing mills, paddy mill, rice mill, paddy machine, rice milling machine - Duration: 9:46. stone processing technology & machines 166,762 views

Rice Milling Industry News | RiceMilling.com

"Minister says paddy should be processed and sold in the area where it is produced" Minister for Agriculture V.S. Sunilkumar has said here that small rice milling units would be established under the aegis of local self-government bodies for processing paddy produced in the area.

RiceBran Technologies Inc. Reports 2019 Year End …

24.03.2020 · THE WOODLANDS, Texas, March 24, 2020 /PRNewswire/ — RiceBran Technologies (RIBT) (also the "Company" or "RBT"), a global leader in the production and marketing of value-added products derived ...

Paddy to Rice Conversion Process, Rice …

Paddy separating: rice separator separates the unhusked paddy from the brown rice. Whitening: The Rice milling is the process that helps in removal of hulls and brans from paddy grains to produce polished rice. White rice is the result of further milling by machines that rub the grains together under pressure. This abrasion removes the bran ...

IR Application in Rice Processing – Professor Pans ...

The research results revealed that the infrared drying technology was superior to the conventional rice drying method, especially in terms of its higher drying rate, improved rice milling quality, and reduced environmental impact.

rice+milling+machine - View all …

Browse results for rice+milling+machine on Carousell Philippines. Brand new and used for sale. Chat to buy!