CN104195420A - High-chrome wear-resistant …

The invention discloses a high-chrome wear-resistant cast iron material and a heat treatment method. The high-chrome wear-resistant cast iron material is prepared from iron as a main raw material, and carbon, silicon, manganese, sulphur, phosphorus, chrome, molybdenum, nickel and copper as auxiliary materials in manners of melting and casting after preparation.

Analysis of the High Chromium Cast Iron Microstructure ...

Analysis of the High Chromium Cast Iron Microstructure after the Heat Treatment D. Kopyci ński, E. Guzik, D. Siekaniec *, A. Szcz ęsny AGH University of Science and Technology, Mickiewicza 30, 30-059 Kraków, Poland *Corresponding author. E-mail address: [email protected] Received 30.04.2014; accepted in revised form 09.05.2014 Abstract

Alloy data sheet high chrome white iron 25% | …

ASTM A532 Class III Type A. The 25% Cr alloy is the most common high chrome white iron poured at Penticton Foundry. This alloy has great abrasion resistant properties especially against gouging, grinding and scratching. 25% Cr material can be machined to meet tighter tolerances like those found in pump and piping type castings.

High-chromium (22-34 per cent) Cast Iron Alloys and Their ...

thermal treatment was carried out which consisted of the austenisation at 975°C for 1 h, cooling by moving air down to 300 °C, and keeping alloy samples for 8 h. The results of cast alloys were compared with those of thermal treatments to determine the existence of a decrease in the wear-out properties of high chrome alloys.

Heat treatment process for high chromium …

Heat treatment of high chromium grinding ball is the main method to obtain good wear resistance. The research on high chromium cast iron ball mainly focuses on stone composition selection, heat treatment process determination, modifier selection, good carbide type and wear mechanism.

Heat Treating of High-Alloy White Irons :: Total …

An austenitizing heat treatment usually comprised heating at temperatures between 750 and 790°C (1380 and 1450°F) with a soak time of 8 h. Air or furnace cooling, not over 30°C/h, was conducted followed by a tempering/stress-relief heat treatment. Refrigeration heat treatment is the more commonly practiced remedy for low hardness today.

Effects of Heat Treatment Process on …

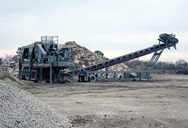

High Chromium wear-resistant cast iron is widely used because of its excellent wear resistance. High Chromium cast iron grinding balls are widely used in cement, mining, thermal power generation, etc. To improve the production and heat treatment process of grinding balls and actively explore the relevant laws in the production process has a good guiding role for the …

High Carbon/High Chrome Tool Steel - Cincinnati Tool Steel

High Carbon/High Chrome Tool Steel As the result of its special annealed structure, developed and tested over a period of several years, AISI Type D2 is the ideal grade for maximum production runs. Its machinability is superior to any of the similar types of tool steel. It also has excellent wear-resistance and deep hardening

High Chrome Oil Quenching Casting Iron Balls Cr …

Special High Chrome Oil Quenching Casting Iron Ball Cr:20-30 For Ball Mill Grinding . THE PROCESS LINE OF PRODUCTION: raw materilals----scientific proportioning----electric furnaxe smelting----assay before furnace----mould forming----polishing----Heat treament----Dimension test----Hardness test----Packing----Transportation----Sea freightWe are one of the largest factory …

Heat treatment and effects of Cr and Ni in low alloy steel

Heat treatment and effects of Cr and Ni in low alloy steel MOHAMMAD ABDUR RAZZAK ... heat treatments were done for 2 h at higher temperatures, it is logical to expect that the precipitating elements will be completely in solution at the chosen heat treatment temperature.

Microstructural Modifications of As-Cast High …

4-9-2008 · The effect of each heat treatment on the hardness of the alloy was correlated with the attained microstructure. Advertisement. Springer Nature is making SARS-CoV-2 and COVID-19 research free. View ... Microstructural Modifications of As-Cast High-Chromium White Iron by Heat Treatment.

Effect of Heat Treatment Parameters on the Mechanical and ...

This study examines the effect of heat treatment at three different temperatures of 800˚C, 950˚C and 1100˚C on the microstructure and mechanical properties of low-alloy steel with an addition of manganese, chrome and lead. To determine an impact of the applied heat treatment operations,

Confused about Annealing / Heat Treating …

Confused about Annealing / Heat Treating Terminology? In the broadest sense annealing is the process of heating an alloy to an elevated temperature to promote a homogenous chemistry, equiaxed microstructure and uniform mechanical properties to produce what is essentially stress free, or “soft” material.

What is Chrome White Iron – ASTM A532? | …

The heat treatment should be designed based on the chemistry of the part, its section thickness and desired properties. Applications for Chrome White Iron. Pumps, impellers and suction or bearing liners are some of the most common uses for chrome white iron.

Heat Treatment of Cast Irons | 2018-12-12 | …

Common Heat Treatment for the Specific Cast-Iron Types. High-alloy (e.g., high chromium, high nickel-chromium) white irons can be heat treated. For example, nickel-chromium white-iron castings are given a stress-relief heat treatment because, properly made, they have an as-cast martensitic matrix structure.

Influence of Heat Treatment on the …

The aim of this work was the study of the heat treatment optimisation of high chrome steels used for the manufacture of rolling rolls in order to obtain a final product with a high hardness and wear resistance and taking into account the very large dimensions typical of these products. The effect of modifying the maintenance temperature and time during the different phases of the heat ...

High Chromium Cast Iron: Part One :: Total …

High chromium cast irons (HCCI’s) exhibit very good mechanical properties and offer benefits for a range of manufacturing applications. With carefully controlled heat treatment the cast iron properties can be further influenced to yield higher strength and ductility depending on the desired application.

Blue Light Industry | foundry & heat treatment

Blue Light Industry, a subsidiary of the UAE based engineering conglomerate Trinity Holdings, is a leading provider of engineered sand castings, heat treatment and electroplating service. For over 20 years, Blue Light has been committed to offer quality services to diverse industry requirements.

Stainless Steel - Heat Treatment - AZoM.com

Stainless steels are heat treated for a variety of reasons. Treatments include annealing, hardening and stress relieving. They are used to restore desirable properties e.g. corrosion resistance to metal altered by prior fabrication operations or produce hard structures able to withstand high stresse