Process Fans Used in Cement Industry - Reitzindia

Raw mill exhaust fans or stack fans are also called as de-dusting fans. In cement industry raw mill exhaust fans handle 2.2 ton of exhaust gases for the production of 1 ton of clinker. Raw mill exhaust fans are operated with very adverse situations because the fan handles mainly gases such as CO2, N2, NOx and Sox along with some dust particles.

OK™ Mill working principle by FLSmidth - YouTube

11.02.2017 · The OK™ mill - the most reliable and efficient mill for raw and cement grinding - Duration: 2:47. FLSmidth 11,793 views

raw mill fan cement plant - splendidkitchens.co.za

Raw Mill Fan Upgrade . Cement plants form a challenging environment for rotating equipment Significant amounts of silica dust occur as a by-product of certain construction processes Over time this dust subjects rotating equipment including Raw Mill fans to high levels of erosion which ultimately reduces the plants output over time . Get Price . Get Price. ENERGY AND EXERGY ANALYSIS OF THE RAW ...

What is raw mill feed | how raw mill feed works in …

10.03.2017 · Working of raw mill feeder in cement plant is described here. Mechanical Engineering point of view about this raw mill feeder area is explained here. Mechanical Engineering point of view about ...

working of vertical raw mill in cement plant

mill classifying plant vertical mill plant packing cement packing machine daswell is a working of raw mill fan in cement plant. purpose of cement raw. Get Price . 150 mm cement plant mill grinding balls ... clinker suppliers.vertical cement mill process plant,cement production line,cemnt raw mill in cement plant working principle of cement ball mill : Get Price. zk ball mill_cement mill_rotary ...

Cement mill working - ontwerpbureau …

Cement mill working. Cement manufacturing components of a cement plant This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln the cement mill etc For information on materials including reactions in the kiln see the Clinker pages [email protected] Get a Quote Chat Online. PRODUCTS …

Process Fans Used in Cement Industry - LinkedIn …

Raw mill exhaust fans: Raw mill exhaust fans or stack fans are also called as de-dusting fans. In cement industry raw mill exhaust fans handle 2.2 ton of exhaust gases for the production of 1 ton of clinker. Raw mill exhaust fans are operated with very adverse situations because the fan handles mainly gases such as CO2, N2, NOx and Sox along with some dust particles.

Manufacturing process | Lafarge - Cement, …

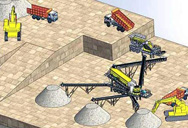

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km. The limestone is excavated from open cast mines after drilling and blasting and loaded onto dumpers which transport the materials and unload into hoppers ...

Stacker and reclaimer systems for cement plants

Stacker and reclaimer systems for cement plants. Heavy-duty performance 2 Ideal for both prehomogenisation and buffer storage of raw materials, FLSmidth stacker and reclaimer systems have an impressive track record of performance. FLSmidth has commissioned some of the largest stackers and reclaimers in the cement industry, matching kiln through-puts of up to 12,000-13,000 tpd. We …

Centrifugal Fans Cement Plants - dokaendustri.com.tr

KilnI.D.Fan forCementPlants Kiln I.D. fan for a cement plant Technical Data: Volumeflow: 193,0m 3/s Totalpressureincrease: 9000Pa Temperature: 380°C Shaftpower: 2243kW Efficiency: 82% Dust: 30g/m 3 Speed: 980rpm Impellerdiameter: 3674mm Tipspeed: …

Raw Mill Fan Upgrade | Case Studies | Howden

Cement plants form a challenging environment for rotating equipment. Significant amounts of silica dust occur as a by-product of certain construction processes. Over time this dust subjects rotating equipment, including Raw Mill fans, to high levels of erosion which ultimately reduces the plant’s output over time. At Tarmac (Dunbar, UK), their existing Raw Mill fan was replaced with an ...

cement-plant-operation-handbook - LinkedIn …

Cement mill Cement sibs -1,14 4 Crusher Limestone Iquarry Clinker Cement CEMENT PLANT SCHEMATIC 4114 PROCESS FLOW Shipping Clinker silos Raw mill Limestone stockpile Gypsum Blending Additives silos Clay Silica Iron 1 INTRODUCTION Cement is "a substance applied to the surface of solid bodies to make them cohere firmly" or, more specifically, "a powdered substance …

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL …

Vertical roller mill for cement grinding [13]. VRM shown in Figure-1 uses hydraulically hard- pressed conical shape 2-4 rollers against the horizontal revolving grinding table. To enhance comminution, the axes of table and rollers do not traverse in the plane of the table and approximately 150 inclination angles between roller axis and table, the relative motion appertain both sliding and ...

Cement mill - Wikipedia

Cement milling is the largest user of electric power on a cement plant, and because they can easily be started and stopped, it often pays to operate cement mills only during "off-peak" periods when cheaper power is available. This is also favourable for electricity producers, who can negotiate power prices with major users in order to balance their generating capacity over 24 hours. More ...

The cement kiln - Understanding Cement

Manufacturing - the cement kiln. Most Portland cement is made in a rotary kiln. Basically, this is a long cylinder rotating about its axis once every minute or two. The axis is inclined at a slight angle, the end with the burner being lower. The rotation causes the raw meal to gradually pass along from where it enters at the cool end, to the hot end where it eventually drops out and cools ...

Cement Production | Cement | Howden

Once the raw materials have been crushed into raw meal, they are transported to the kiln and Howden fans play an important role in super heating the meal into the cement clinker and then to cool the clinker. The clinker then has gypsum added and is moved into the cement mill …

Raw Mill,Raw Mill In Cement Plant - hotcrusher.com

Raw mill is mainly used in grinding raw materials and end products in cement plant. It is also suitable for various ores and other materials metallurgy, mine, stone and construction. Besides, it has two forms of milling, one is an open form, and the other is a recycle close form equipped with powder concentrator.

Cement Manufacturing Process | Phases | Flow …

Cement Manufacturing Process Phase 1: Raw Material Extraction. Cement uses raw materials that cover calcium, silicon, iron and aluminum. Such raw materials are limestone, clay and sand. Limestone is for calcium. It is combined with much smaller proportions of sand and clay. Sand & clay fulfill the need of silicon, iron and aluminum.