Jaw Crusher Understand- THEMEBO Mining …

Jaw Crushers liming . In addition to the stationary jaw crushers presented on this page many jaw crusher models are also available as mobile or portable versions uncompromised reliability the core of liming c series jaw crusher is a pinned and bolted nonwelded frame

Understand Jaw Crusher Toggle Seat And P

Understand Jaw Crusher Toggle Seat And P Optimum design and analysis of (the) swinging jaw plate of a single toggle jaw crusher Thesis (PDF Available) · April 2010 with 3,812 Reads DOI: 10.13140/RG.2.1.1369.2880

Impact Crusher VS Jaw Crusher:What Are the …

1) Jaw crusher mainly consists frame, eccentric shaft, large pulley, flywheel, movable jaw, side guard plate, toggle plate, toggle plate backseat, adjustable gap screw, reset spring, fixed jaw and movable jaw, in which the toggle plate also plays the role of insurance.

Understand jaw crusher toggle seat and plate

Understand jaw crusher toggle seat and plate. Toggle plate model Various models based on customers needs Order quantitypcs Not limited Purposes The mining machinery parts are unique steel castings in accurate calculation They are used to adjust the discharge port size of jaw crushers and compensate the abrasion of jaw plates and toggle plate seats . Get a Quote. Related Products. Cedarapids ...

Understand jaw crusher toggle seat and plate

Toggle Plate For Jaw Crusher. Toggle plate Jaw crusher parts The material of toggle plate is high manganese good performance with low abrasion high resistance Jaw crusher parts is widely applied in mining metallurgy construction road building stone and phosphatic industry and . Live Chat

Jaw Crushers - Parker Plant

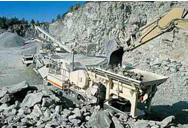

Jaw crushers are used mainly in first stage, primary crushing applications and are ideal for use in quarries and recycling demolition operations. The two main types of jaw crusher produced by Parker are both single toggle designs with the up-thrust toggle RockSizer / StoneSizer model and down-thrust toggle RockSledger model. Base Units . The RockSizer / StoneSizer up-thrust single toggle ...

Jaw crushers, Stationary Jaw crusher series — …

Stationary jaw crushers liming jaw crushers are of the single-toggle type with advanced features for optimized performance, easy maintenance, long life and a low cost per ton. These crushers feature a deep, symmetrical crushing chamber, easy settings adjustment, a large feed opening for its size, and an ideal nip angle that offers smooth material flow and high reduction efficiency.

Jaw Crushers - 911Metallurgist

This crusher is the finest of our lines of jaw crushers which we offer. Others include: Superior, Type “B” Blake, Fine-Reduction and Dodge — sizes, 4 by 6 to 84 by 66 inches. A reciprocating machine, the crushes material in a straight line between jaws — without grinding or rubbing surfaces.

jaw crusher | Gumtree Australia Free Local …

Is a good demonstration of the real machine to understand individual parts. Price is fixed and non negotiable. I also have another Jaw crusher model scale 1:30 for the same price. Message me for further information. Victoria Park Area East Victoria Park. 01/05/2020. Jaw Crusher. $11,000. Pex 250mm x 1200mm Fixed Jaw Crusher from surplus stock due to plant upgrade Used previously in …

Jaw Crusher Manufacturer, Supplier, Trading …

Specifications: JAW CRUSHER 36"*08" : Single Toggle Grease Lubricated,Double Wheel,Chachise Stand , Power 50 HP , RPM 385/400 , Feed Size 6" 150 mm, Production 45 TPH In 2.5"Material Size , Body 40mm MS Sail Plate Make "Vindhya" Model A1 , Weight 9200 Kgs. Features: High efficiency Smooth functioning Easy to handle.

Gyratory VS Jaw Crushers: Advantages & …

No discussion of primary crusher selection would be complete without a comparison of the two leading types: the standard gyratory crusher and the Blake jaw crusher. Although their fields of application overlap to a considerable degree (at least in the realm of primary crushing) there is no real conflict between these two machines; one supplements the other and, between them they very ...

Small Jaw Crusher - 911Metallurgist

The 911MPEJAC23 is a Small Jaw Crusher of 2.25" X 3" manufactured to easily crush any rock from 2" (50mm) down to a D50 of 700 micron (28 Mesh) which also correspond to a crushed discharge P80 size of 80% passing 1400 microns or 14 mesh. The discharge opening (closed-side-setting) of this 55 mm X 75 mm "big-small crusher" you can adjusted with a wrench.

Small Jaw Crusher - 911metallurgist.com

The 911MPE-JAC34 or 3" x 4" (75 x 100 mm) is our biggest Small Jaw Crusher. Handcrafted in Canada, is designed crush rocks/ore of any type (gold, silver, copper, granite, cement, bricks, etc.) 3” (75mm) in size down to 50% passing its CSS closed side setting of 1/8". With a 375 RPM overhead eccentric, and equipped of a 3 HP electric motor or 6.5 HP gasoline engine, this small primary rock ...

MBMMLLC.com: Crushing granite with a jaw …

26.11.2014 · The 10"x16" jaw crusher was used to crush these 8" thick slabs of granite as a test. This crusher will crush 5+ tons/hr at 1" minus and is powered with a 20 hp electric motor. The crusher …