Blast Furnace Slag - Material Description - User ...

Granulated blast furnace slag is a glassy granular material that varies, depending on the stone composition and method of production, from a coarse, popcornlike friable structure greater than 4.75 mm (No. 4 sieve) in diameter to dense, sand-size grains passing a …

Blast Furnace Slag - Material Description - RMRC

Granulated blast furnace slag is a glassy granular material that varies, depending on the stone composition and method of production, from a coarse, popcornlike friable structure greater than 4.75 mm (No. 4 sieve) in diameter to dense, sand-size grains passing a …

MPA - Mineral Products Association - Products

Granulated Blast furnace slag (GBS) is a light coloured 0/4mm glassy sand produced by the rapid quenching of molten blast furnace slag using large volumes of water. Production and Processing GBS or Granulate as it is sometimes known is produced by rapidly cooling molten Blast furnace slag with water as the slag is tapped from the furnace.

Characteristics and applications of iron and steel slag ...

Steelmaking slag Because of its hydraulic property and the large bearing capacity it can provide, steelmaking slag is used as a road base course material. With high particle density and hardness, this slag has superior wear resistance and for this reason is used as an aggregate for asphalt concrete.

Slag Atomising Technology (SAT): Strategic management of ...

Graph 1 shows the analysis result of XRD of slag processed by SAT and shows the formation of dicalcium ferrite {2CaO- Fe 2 O 3} and larnite (β- 2CaO-SiO 2}.Besides, this new technology enables the slag to take on a granulated-round shaped form which comes into good use in concrete mixtures. The stone ingredients of PS balls are nearly the ...

Types of iron and steel slag : NIPPON SLAG ASSOCIATION

The molten slag flows into a cooling yard, where it is cooled slowly by natural cooling and by spraying with water. This results in a crystalline, rock-like air-cooled slag. Granulated slag The molten slag is cooled rapidly by jets of pressurized water, resulting in a vitreous, granulated slag.

Mohs Hardness (Typical) of Abrasives - Reade

Mohs Hardness (Typical) of Abrasives table from READE. Abrasive blasting for surface preparation is an important step in providing a foundation for protective coatings. For years, tests have concluded that high-performance coatings provide excellent corrosion protection and durability when applied over a blast-cleaned surface with a consistent anchor profile.

Common Uses for Slag | National Slag Association

Molten slag is generally placed into ground bays for cooling. Both BOF and EAF slags are somewhat heavier than Blast Furnace Slag and most quarried rock material. Uses include. Blending with many other products such as granulated slag, fly ash and lime to form pavement material, skid resistant asphalt aggregate and unconfined construction fill.

Slag - Wikipedia

The slag can also be used to create fibers used as an insulation material called slag wool. Basic slag. Basic slag is a co-product of steelmaking, and is typically produced either through the blast furnace - oxygen converter route or the electric arc furnace - ladle furnace route.

Blast Furnace Slag | National Slag Association

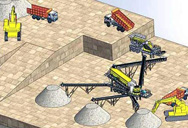

Blast furnace slag is allowed to slowly cool by ambient air, is processed through a screening and crushing plant and is processed into many sizes for use primarily as a construction aggregate. Common uses are as aggregates in ready-mix concrete, precast concrete, hot mix asphalt aggregate, septic drain fields and pipe backfill.

Phosphorus Slag - an overview | ScienceDirect Topics

Granulated phosphorus slag is a latent cementitious material but less reactive than granulated blast-furnace slag at early age due to the lower Al 2 O 3 content and the presence of P 2 O 5 and F. A hydraulic index of phosphorus slag is defined …

Ground Granulated Blast Furnace Slag in Concrete and its ...

The ground granulated blast furnace slag (GGBFS) is a by-product of iron manufacturing which when added to concrete improves its properties such as workability, strength and durability. This material is obtained by the heating of iron ore, limestone and coke at a temperature about 1500 degree Celsius. The process is carried out in a blast furnace.

Nonferrous Slags - Material Description - RMRC

Nonferrous Slags - Material Description ... In Georgia, granulated slag is reportedly added to hot mix asphalt mixes in conjunction with limestone aggregate to increase stability and reduce Marshall flow. (17) Wear Resistance: The superior hardness and abrasion resistance of copper slag aggregates compared with most conventional aggregates ...

Ground Granulated Blast Furnace Slag (GGBS) | stone ...

May 09, 2018 · Ground Granulated Blast Furnace Slag (GGBS) The importance of Ground Granulated Blast Furnace Slag (GGBS) lies in its greener way to become a substitute in concrete material. GGBS being a waste material, it needs proper method for disposal. So incorporating this waste material in concrete can reduce the depletion of conventional concrete components …

(PDF) Opportunities for valorization of steel slags

In this study, conventional concrete M30 grade concrete mix was designed with Ground Granulated Blast Furnace Slag (GGBS) to cement and Copper slag (CS) to fine aggregate as partial replacement.

Experimental studies of slag filter for drinking water ...

The slag modified filter with Iranian natural zeolite and blast furnace slag showed 98.98% turbidity removal, 51.95% hardness removal and 11.02% EC reduction (Abdolahnejad et al., 2014). The turbidity removal was mainly due to stone precipitation and adsorption which is in unison with the previous results.

Blast Furnance Slag - User Guideline - Portland Cement ...

Fineness: Granulated blast furnace slag is a glassy granular material, and its particle distribution, shape, and stone size vary, depending on the stone composition and method of production, from popcornlike friable particles to dense, sand-size grains. Pelletized blast furnace slag, in contrast to air-cooled and expanded blast furnace slag ...

(PDF) Utilization of carbonated and granulated steel slag ...

Utilization of carbonated and granulated steel slag aggregate in concrete.pdf Utilization of carbonated and granulated steel slag aggregate in concrete Bo Pang, Zonghui Zhou